Unlock Your Business Potential with Octopart's Partner Solutions

Our tools deliver powerful results, and our customizable Partner Solution package allows you to fine-tune your strategy to match your unique business needs.

Inventory Listing

Marketing Solutions

Data Intelligence

API for business

Embedded Experiences

List your inventory on Octopart

Access millions of engineers, procurement professionals and designers looking to source components for their next product. Powered by Nexar’s API, your inventory is searchable by Octopart.com customers, engineers designing with Altium Designer and Altium 365, or buyers using in-house procurement tools.

Marketing Solutions

Leverage our marketing solutions to put your brand in front of a global audience of industry professionals. With flexible and dynamic offerings, we can help you build and customize your campaigns to maximize impact.

Data Intelligence

The analytics we offer will empower you to make smarter decisions by providing access to valuable industry insights you can’t get anywhere else. Learn which parts are the most popular, discover the most searched parts with zero inventory, and more with packages tailored for your business.

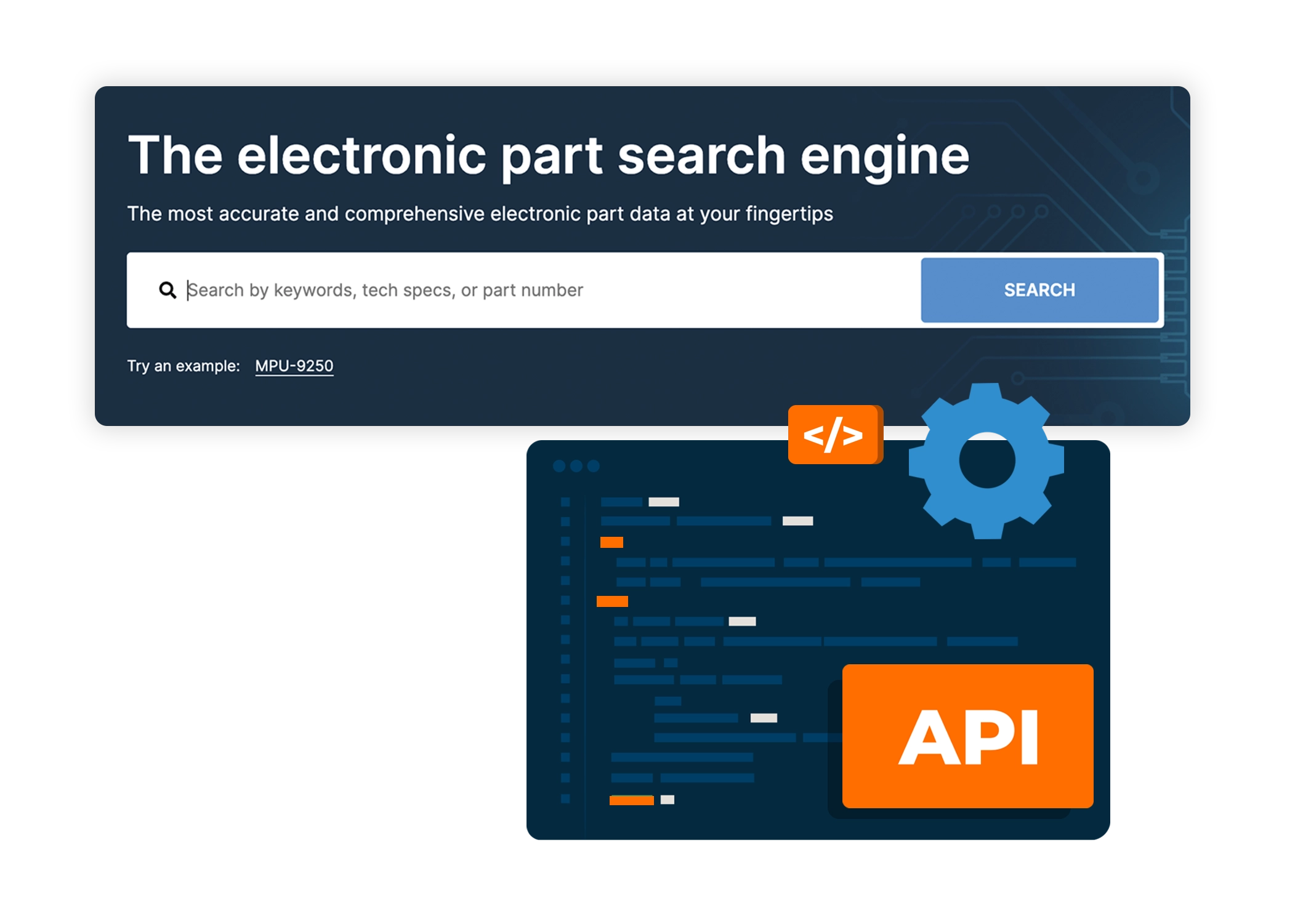

API for business

The Nexar API is a comprehensive solution perfectly tailored to meet the diverse needs of our valued partners. As a distributor, you now have the opportunity to enhance your website through verified descriptions, detailed specifications, and immersive CAD models, revolutionizing the way you showcase products and empowering your customers with accurate and comprehensive information.

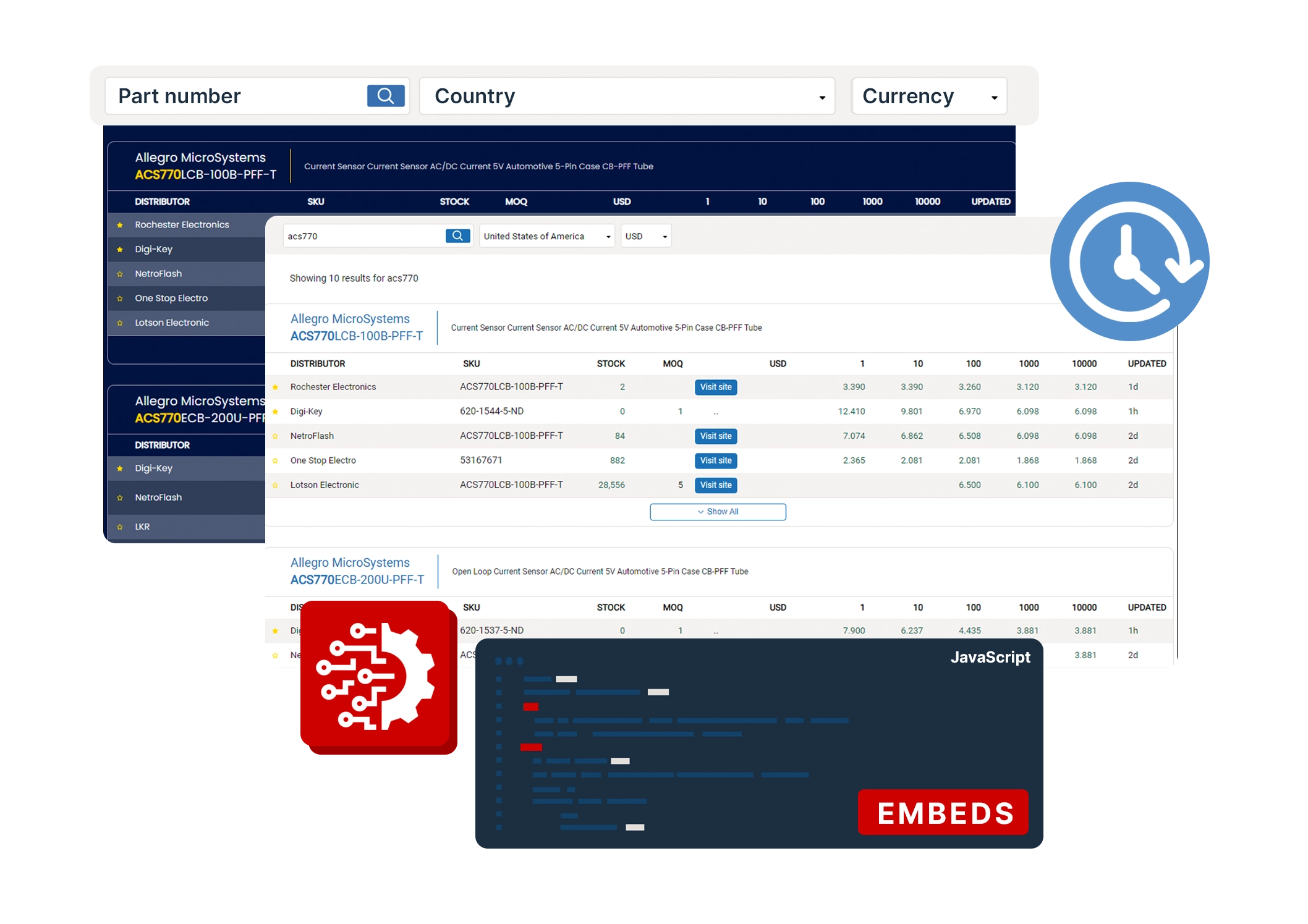

Embedded Experiences

With the integration of Nexar Embeds, the Stock Locator tool showcases distributor inventory and pricing for component manufacturers, empowering customers with valuable data for informed purchasing decisions. This tool streamlines procurement with real-time inventory availability and price comparison, enabling customers to choose the most cost-effective options.

Free and easy-to-use, designed for our industry partners, with dedicated support from the Nexar API team through integration.

Customize the inventory listing to market your products, with options to display currency, country, and more.

Seamlessly integrate the tool into your site with custom colors and fonts to match your branding.

Discover what our valued partners have to say about Octopart

An Ecosystem of Solutions

Our innovative solutions are transforming the electronics industry, empowering designers and businesses alike. Explore the wide range of services we offer to cater to your specific needs:

Altium Designer

Unified PCB design software environment

Octopart.com

Industry leading search engine for electronic components

Nexar API

Provides real-time visibility and insights into your operations

Altium A365

Cloud-based collaborative PCB design platform

Spectra Industry Intelligence

Actionable industry analysis and data solutions

Upverter Modular Design

Easy-to-use modular PCB design solution

Get started with Octopart Partner Solutions Today!

Join our Partners

See how your parts will appear on Octopart, the most accurate and comprehensive electronic parts database.